Business Area

Digital Transformation with Digital Twin

Transformation

We pursue digital transformation for big data validation, correction, and interpretation technology in all fields of the energy industry.

Data Validation and Correction

-

Data correction

The accuracy of measurement is improved through statistical optimization methods that correct the quantity value of

the measuring instrument containing error to satisfy the material balance/component balance/energy balance constraints. -

Use of data correction

- Sensor Check

Detection of abnormalities in sensors or equipment through error analysis of sensor values

- Virtual Sensor

Generation of data for locations where physical sensor installation is difficult

- Data Analysis

Used for facility performance monitoring, maintenance, and optimal operation

- Sensor Check

-

Data engineering

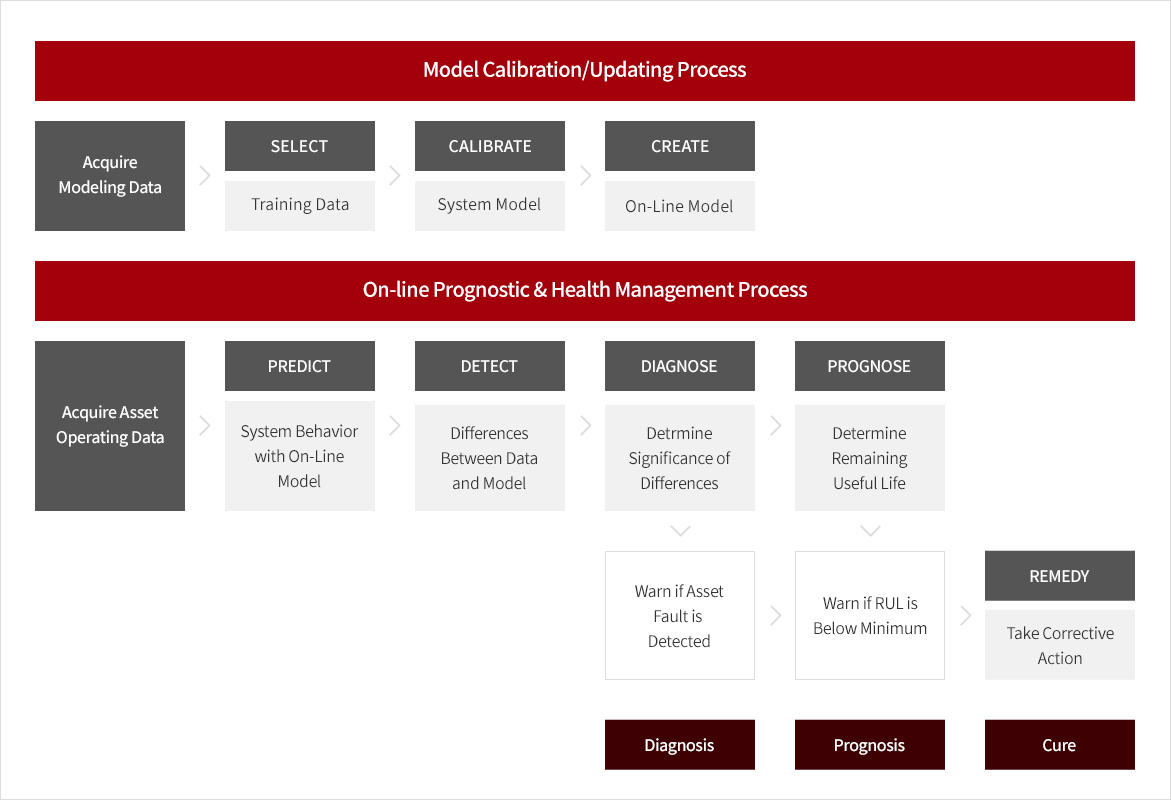

- Abnormality detection and diagnosis

Detection and diagnosis of equipment abnormalities using the rate and

amount of change in past and present data - Improvement of utility

Derivation of a control system optimization operation plan including virtual sensor technology

- Industrial information standardization

Reflection in plant design through analysis of design data and operation data

- Abnormality detection and diagnosis

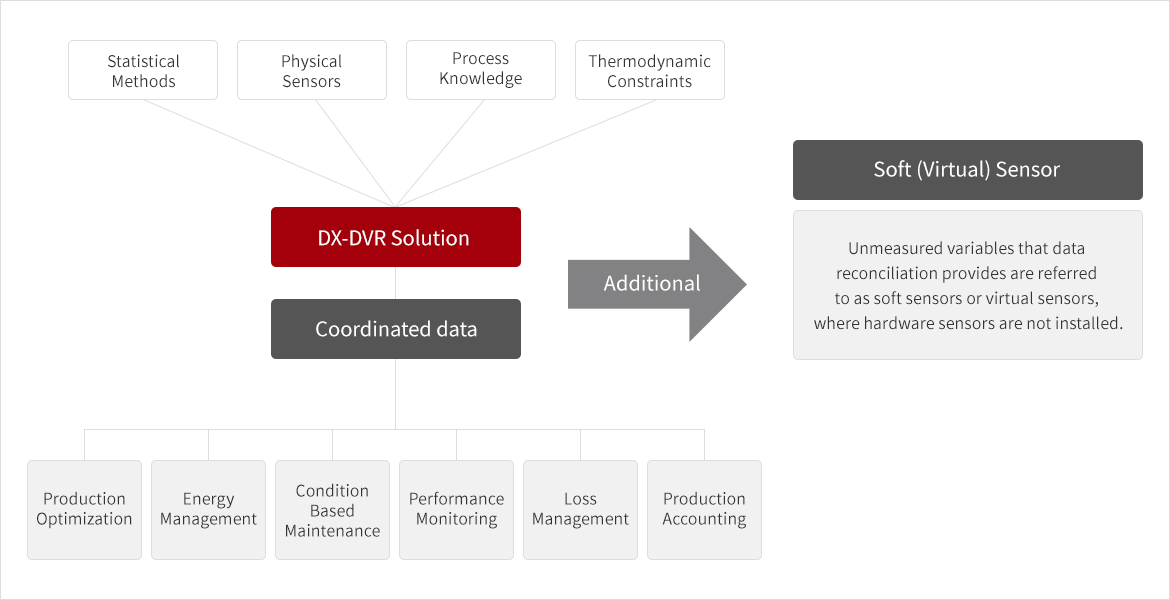

DVR & Virtual Sensor

Our DVR (Data Validation & Reconciliation) solution can improve the efficiency of various optimization solutions by applying correction technology to measured

sensor data to increase the accuracy of the data. This solution also enables data generation in locations where physical sensors cannot be installed.

SureSense

SureSense software combines accurate online anomaly detection, automated Virtual SME diagnostics, and real-time..