Business Area

Digital Transformation with Digital Twin

Transformation

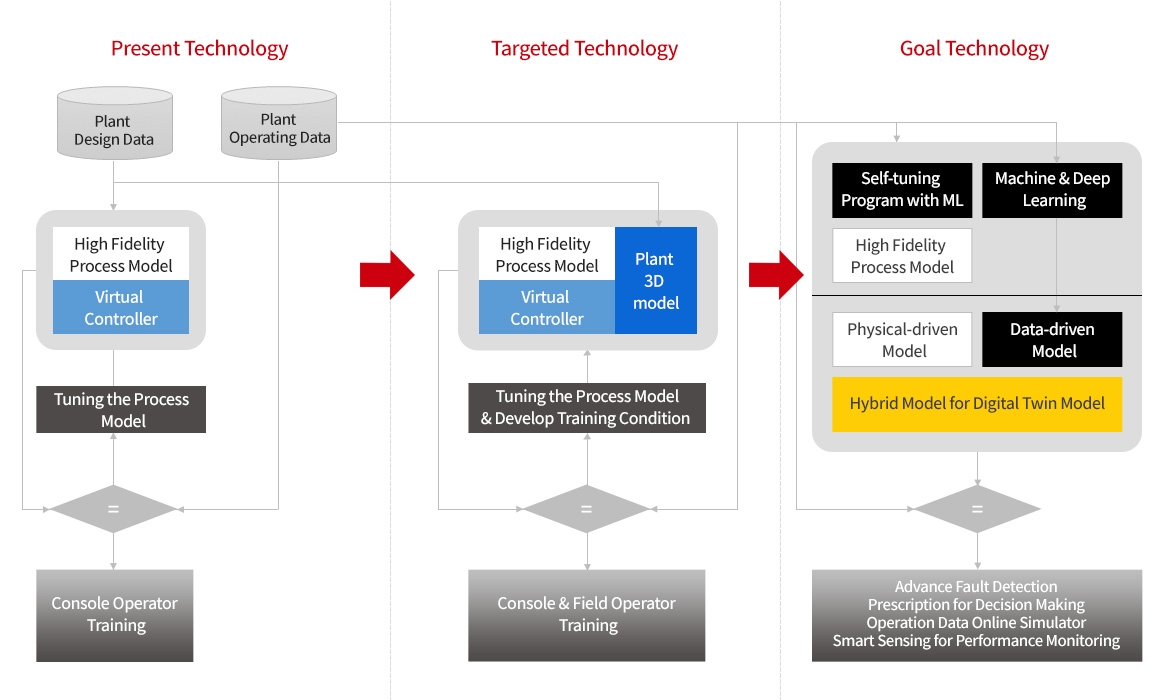

We pursue digital transformation in which simulators can be applied to all fields of the energy industry.

Simulator

-

Plant simulator

As a tool for training operators, event replay and analysis, and engineering development, it implements the equipment and

control system of an actual power plant with high fidelity. -

Types of simulators

- Engineering

Used for the verification of dynamic characteristics of design for system, development of control logic, and virtual test runs

- Operator Training

Used for training to improve the response ability of control room operators in normal and abnormal situations

- Immersive Training

Used in VR technology linked convergence training to improve the training effectiveness of field operators

- Engineering

-

Future of simulators

- Expansion of industrial fields

Integrated energy operation such as new & renewable energy systems and microgrids

- Expansion of technology application

Comparative analysis of system performance, development of control algorithm,

data generation through failure simulation, etc. - Digital twinization

Optimal operation system configuration through linkage with actual operation data

- Expansion of industrial fields

시뮬레이터의 확장

Control Room Operator Training

Plant Start up, Shut down

Emergency Operation by Malfunctions

Trainee Proficiency Review

Control Room & Field Operator Training

3D Model and VR

Combined Plant Data

Safety Training

Learning Management System

Operation & Maintenance Optimize

Online Dynamic Performance Monitoring System

Anomaly Detection using DT

Optimal Solution for Asset

- Control Logic V&V

- Virtual Commissioning

- Operator Training

- Field Operator Training

- Emergency planning, training, crew

interactions and team building - User-friendly data base

- Optimization

- Asset Performance Management

- Advanced Control

- First-principle high-fidelity process modeling

- Virtual control system implementation

- Plant Operation Knowledge

- VR & AR Applied

- Database Interface

- Plant Emergency Planning

- BigData

- ML & DL

- Optimization