Business Area

Digital Transformation with Digital Twin

Our Business

We are applying digital twin-based cloud smart EMS to improve energy efficiency in general industrial complexes,

complex industrial complexes, and individual factories and buildings.

D(x)EMS

- - Continuous upgrade of energy optimization level by linking equipment and process data to digital twin

- - Failure prediction and response plan derivation through continuous performance monitoring, failure prediction through abnormality detection,

and response plan derivation of energy overconsuming equipment, etc. - - Presentation of an optimal economic operation plan considering greenhouse gas reduction

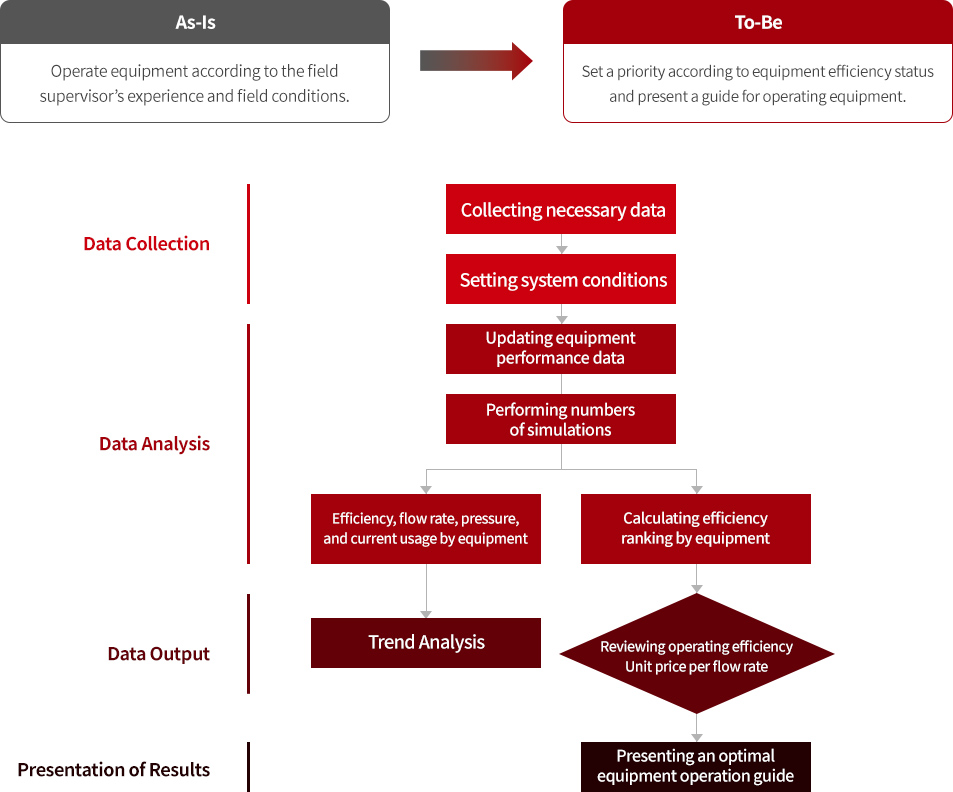

DxEMS (Digital twin-based energy control system)

- - Flexible applicability: FEMS, BEMS, HEMS & CEMS

- - Cloud-based economics: Field cost reduction

- - Digital twin-based optimization: State-based operation optimization

- - Convergence of domain knowledge and data science

DxCOMP

- • Modeling for various equipment consisting of compressors and presentingan optimal operation guide through simulation with DxCOMP

Digital Twin Model Development

- • Building a big data analysis system

- - Acquire long-term accumulated raw data and event data to analyze performance trend and equipment status

- - Build a DB system that extracts necessary data from the field server for compressors and manage it on a separate server.

- • Developing a performance model

- - Develop a model that can simulate the performance of the compressor system according to external environmental input and output conditions

- - Realize a simulation of the performance of major components and the discharge state of the header outlet.

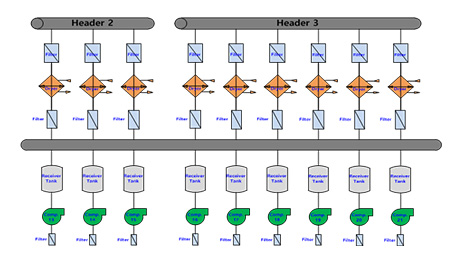

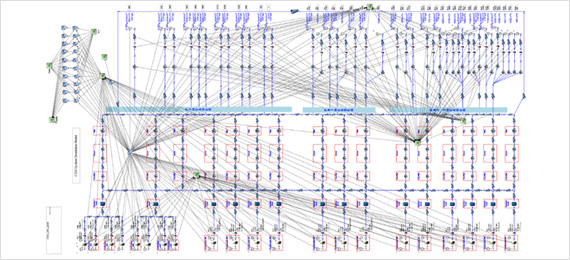

System Concept Modeling Diagram

System Concept Modeling Diagram

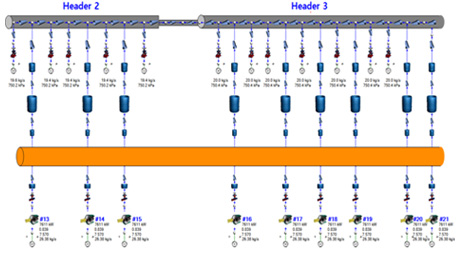

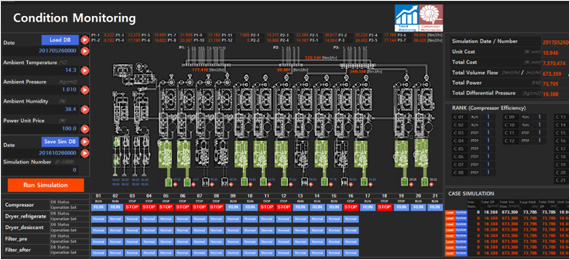

Performance Simulation Development

- • Simulation according to external environmental variables (atmospheric temperature, atmospheric pressure, humidity, etc.)

- • Simulation according to equipment load (whether compressor is operating, whether dryer is operating, whether filter is clogged, etc.)

- • Simulation based on the current operation status by acquiring DB operation data

- • Performance simulation for each compressor line

Condition Monitoring GUI

System Performance Simulation Model